As the world confronts the challenges of climate change and environmental degradation,

the construction industry is embracing sustainable building practices to reduce its ecological footprint.

In this quest for eco-friendly solutions, Wood-Plastic Composite (WPC) sandwich panels have emerged as a key player,

offering a range of environmental advantages that make them a preferred choice for green building projects.

Composed of renewable wood fibers and recycled plastics, WPC sandwich panels provide an innovative and

efficient building material that promotes circular economy principles and reduces reliance on traditional resources.

In this article, we will explore the environmental advantages of WPC sandwich panels, focusing on their eco-friendliness,

reduced carbon footprint, waste reduction, and potential to shape a greener and more sustainable future for the construction industry.

WPC sandwich panels present a powerful argument for building green due to their significant environmental advantages.

By utilizing renewable and recycled materials, these panels contribute to reduced deforestation and plastic waste, promoting sustainable forestry and circular economy practices.

The low-carbon footprint of WPC panels, coupled with their exceptional thermal insulation properties,

reduces energy consumption and greenhouse gas emissions, making them an eco-friendly choice for energy-efficient buildings.

Additionally, WPC sandwich panels minimize construction waste and contribute to reduced maintenance requirements, further lowering the environmental impact of building projects.

As we delve into the environmental advantages of WPC sandwich panels, it becomes evident that they are building a more sustainable and environmentally responsible future for the construction industry.

Eco-Friendliness: The Power of Renewable Resources

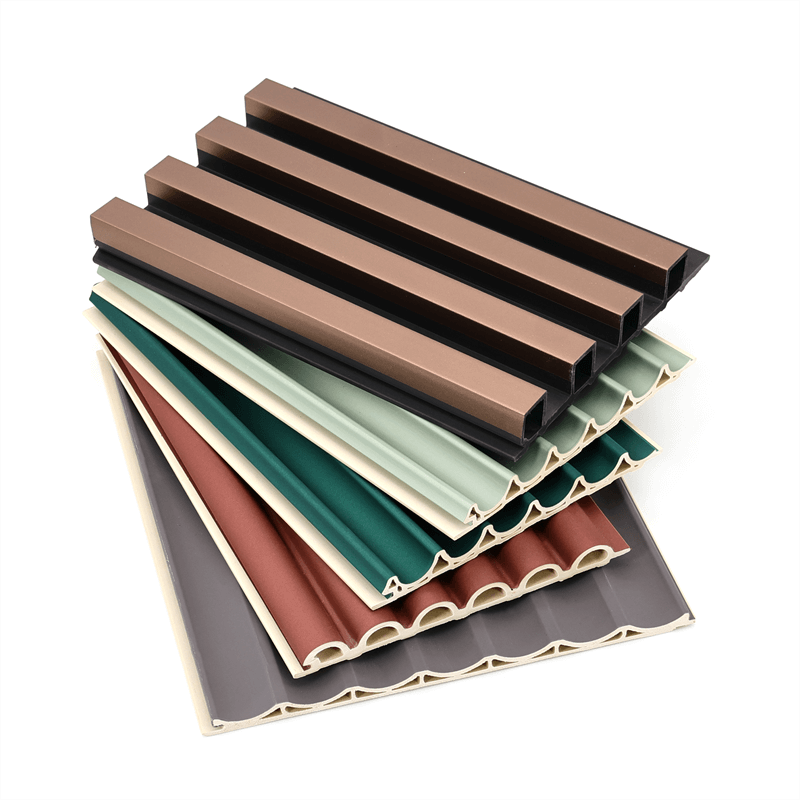

The eco-friendliness of WPC sandwich panels stems from their unique composition, which combines renewable wood fibers and recycled plastics.

The wood fibers used in these panels are sourced from responsibly managed forests, ensuring the conservation and sustainable use of forest resources.

This practice fosters healthy ecosystems, protects biodiversity, and mitigates deforestation, one of the primary drivers of climate change.

Furthermore, the integration of recycled plastics in WPC panels diverts plastic waste from landfills and reduces its detrimental impact on the environment.

By repurposing plastic waste into a valuable building material, WPC sandwich panels exemplify the principles of circular economy,

where materials are continuously reused and recycled, contributing to a more sustainable construction industry.

Reduced Carbon Footprint: Paving the Way to Energy Efficiency

Energy efficiency is a cornerstone of sustainable building practices, and WPC sandwich panels play a pivotal role in achieving this goal.

The exceptional thermal insulation properties of these panels reduce heat transfer, helping to maintain stable indoor temperatures without excessive reliance on artificial heating or cooling.

By promoting energy-efficient buildings, WPC sandwich panels effectively lower energy consumption and greenhouse gas emissions.

The reduced carbon footprint of these panels aligns with global efforts to combat climate change and transition to a low-carbon future, making them an essential component of green building strategies.

Waste Reduction: Embracing Sustainable Manufacturing

In the manufacturing process of WPC sandwich panels, efficiency and waste reduction are prioritized.

The production of these panels consumes less energy compared to conventional materials like concrete or steel, leading to lower industrial emissions.

Additionally, the optimization of material usage and the recycling of excess materials contribute to minimal waste during production.

WPC sandwich panels also play a role in reducing construction waste during the building phase.

Their lightweight nature simplifies transportation and installation, leading to fewer material wastages at construction sites.

As sustainable manufacturing practices become increasingly critical, WPC panels offer a responsible and eco-friendly building solution.

Lower Maintenance Requirements: A Sustainable Investment

The long-term durability and resistance of WPC sandwich panels to environmental factors contribute to lower maintenance requirements for buildings constructed with these panels.

Unlike traditional wood, which may require regular staining, sealing, or replacement due to rot and decay, WPC panels maintain their appearance and structural integrity with minimal upkeep.

By reducing the need for frequent maintenance and material replacements, WPC sandwich panels contribute to prolonged building lifespans and lower environmental impact.

This aspect further solidifies their position as a sustainable investment for the construction industry.

The environmental advantages of WPC sandwich panels position them as a driving force in building green and embracing sustainable construction practices.

Through their eco-friendly composition, reduced carbon footprint, waste reduction, and low maintenance requirements, these panels exemplify the principles of circular economy and energy efficiency.

As the construction industry seeks innovative solutions to build responsibly, WPC sandwich panels emerge as a game-changer,

offering a greener and more sustainable approach to building, where environmental responsibility and efficiency unite to shape a better world for future generations.