Innovation in the construction industry has been at the forefront of modern architectural developments, introducing new materials and technologies to improve building efficiency and sustainability.

One such innovative solution that has gained considerable attention is the Wood-Plastic Composite (WPC) sandwich panel.

This remarkable material combines the strengths of wood and plastic to create a high-performance building product with a wide range of applications.

In this article, we will delve into the technology behind WPC sandwich panels, exploring their composition,

manufacturing process, and the unique properties that make them a game-changer in the world of construction.

WPC sandwich panels have emerged as a revolutionary construction material, leveraging the advancements in wood-plastic composites and sandwich panel technology.

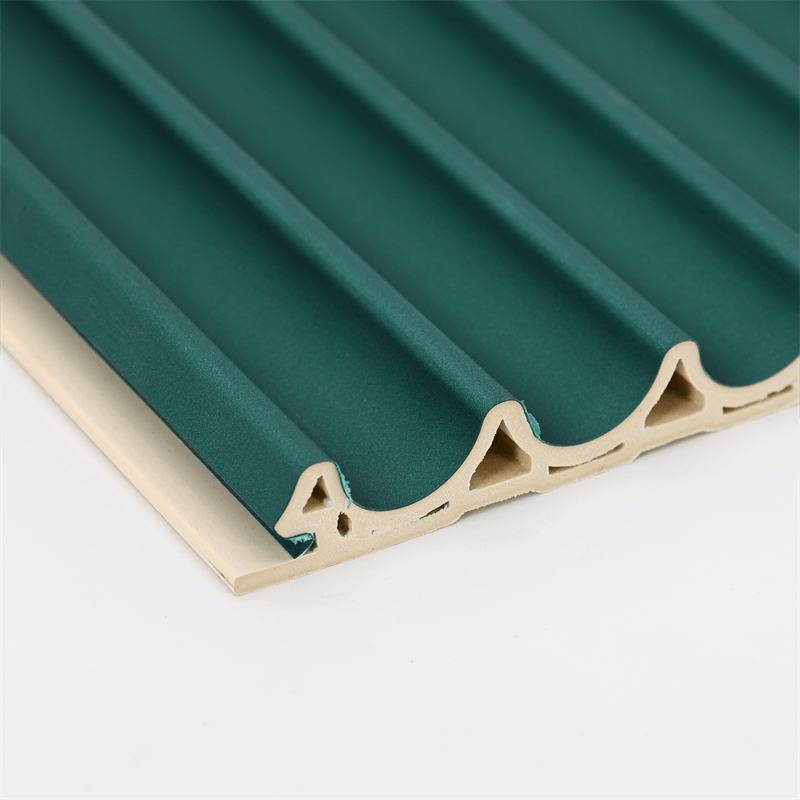

These panels consist of a core made from WPC, sandwiched between two protective layers, offering exceptional strength, thermal insulation, and moisture resistance.

Understanding the technology behind WPC sandwich panels reveals the meticulous engineering and innovative manufacturing processes that contribute to their outstanding performance.

As we explore the composition, production methods, and benefits of WPC sandwich panels, it becomes evident that this technology holds immense potential in transforming the future of construction.

The Composition of WPC Sandwich Panels: A Fusion of Materials

The technology behind WPC sandwich panels starts with their composition.

At the core of these panels lies a Wood-Plastic Composite (WPC) layer, which is a blend of wood fibers or flour and thermoplastic materials, such as polyethylene, polypropylene, or polyvinyl chloride.

The wood fibers provide natural strength, while the thermoplastic matrix binds the composite and imparts desirable properties like water resistance and dimensional stability.

The result is a lightweight yet sturdy core that serves as the backbone of the sandwich panel.

To protect the WPC core and enhance the overall performance, two protective layers are applied on either side of the core.

Typically, these protective layers are made from materials like fiberglass, aluminum, or fiber cement.

These layers shield the WPC core from environmental factors, add rigidity, and provide additional thermal and moisture resistance,

making the WPC sandwich panel suitable for a wide range of applications.

The Manufacturing Process: From Raw Materials to Finished Product

The manufacturing process of WPC sandwich panels is a carefully orchestrated sequence of steps that ensures the quality and consistency of the final product.

The process begins with the preparation of the WPC core material.

Wood fibers or flour are mixed with the thermoplastic matrix in precise proportions, and additives such as coupling agents,

stabilizers, and colorants are incorporated to enhance the composite’s properties.

Next, the WPC core is placed between two protective layers to create the sandwich structure.

The entire assembly is subjected to heat and pressure in a process called hot pressing or compression molding.

During hot pressing, the thermoplastic matrix melts, encapsulating the wood fibers and forming a strong bond between the core and the protective layers.

The specific temperature, pressure, and pressing time are carefully controlled to achieve the desired thickness, density, and mechanical properties of the WPC sandwich panel.

Key Properties and Advantages of WPC Sandwich Panels

The technology behind WPC sandwich panels gives rise to a host of key properties and advantages that set them apart from conventional building materials.

One of the most significant benefits is their exceptional strength-to-weight ratio, making them lightweight yet incredibly sturdy.

This property allows for easy handling, transportation, and installation, reducing labor costs and project timelines.

Moreover, WPC sandwich panels exhibit excellent thermal insulation capabilities,

helping to regulate indoor temperatures and reduce energy consumption for heating and cooling.

The combination of the WPC core and protective layers also contributes to superior moisture resistance,

preventing issues like rot and decay, which are common in traditional wood-based materials.

Additionally, the composition of WPC sandwich panels ensures their resistance to pests, mold, and UV radiation, enhancing their durability and lifespan.

The panels require minimal maintenance, reducing long-term upkeep costs for building owners.

Applications and Future Prospects

The versatility of WPC sandwich panels opens up a wide range of applications in the construction industry.

These panels are commonly used in exterior cladding systems, interior wall partitions, roofing, flooring, and even in the transportation sector for manufacturing lightweight vehicles.

Looking to the future, the technology behind WPC sandwich panels holds great promise for further innovation.

Researchers and manufacturers are continually exploring ways to optimize the composition of WPC materials, improve manufacturing techniques, and expand the range of protective layers.

As sustainability remains a top priority, WPC sandwich panels are likely to play an increasingly vital role in green building projects,

reducing the environmental impact of construction while providing superior performance.

The technology behind WPC sandwich panels represents a significant advancement in modern construction materials.

Through a careful combination of wood and plastic, these panels offer a sustainable, lightweight, and durable solution for various building applications.

Understanding the composition and manufacturing process of WPC sandwich panels highlights the meticulous engineering and innovation that drives their exceptional performance.

As the construction industry continues to evolve, WPC sandwich panels are poised to reshape the way we build, offering an innovative and eco-friendly alternative to conventional materials.