The global construction industry has long been associated with high carbon emissions,

excessive resource consumption, and environmental degradation.

However, a new eco-friendly revolution is underway, driven by innovative building

materials that prioritize sustainability without compromising on performance.

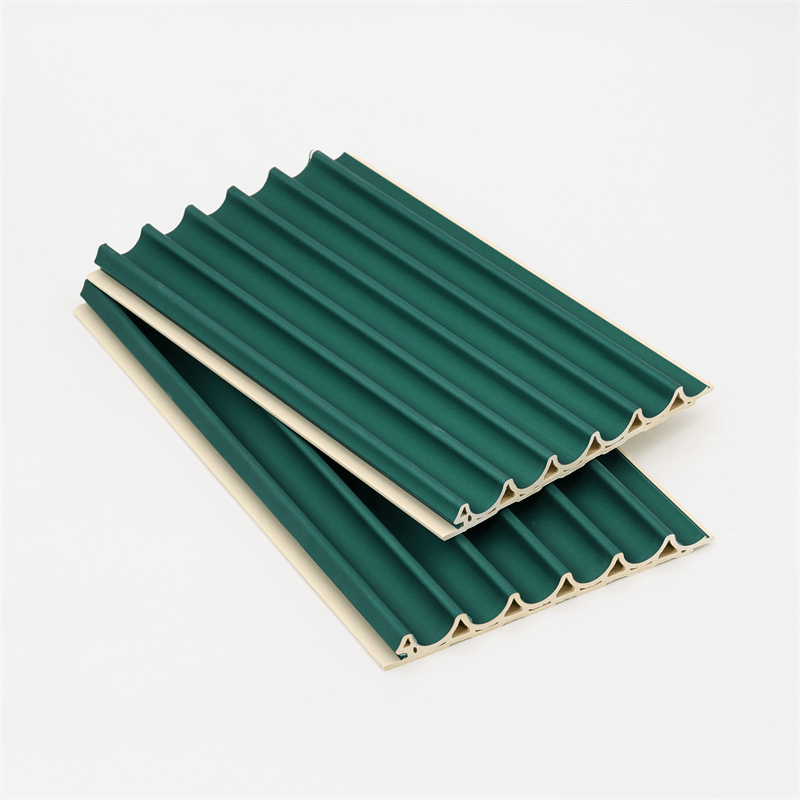

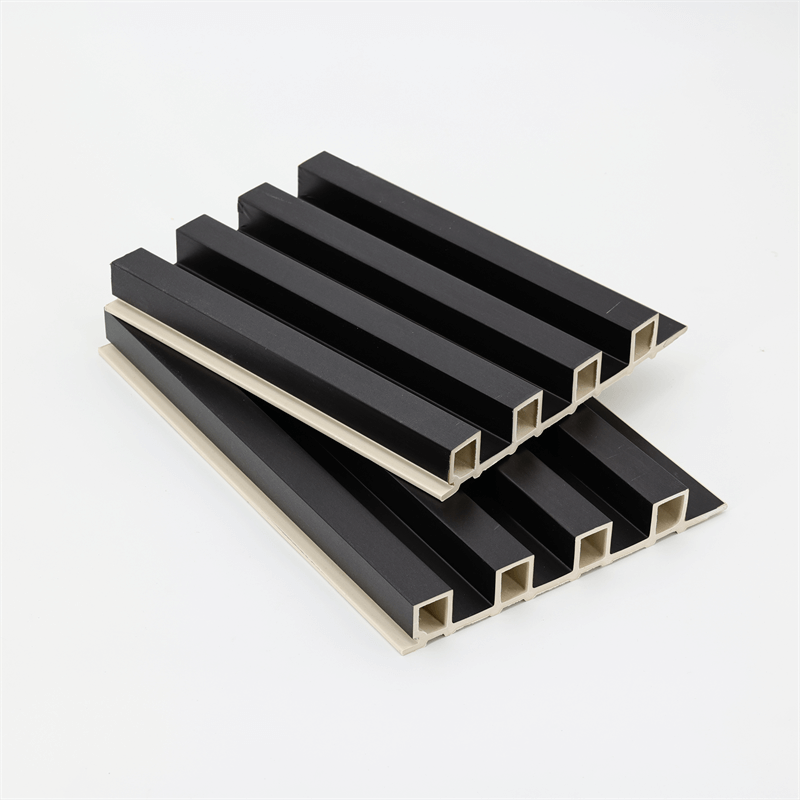

One such revolutionary material that is redefining the construction

landscape is the Wood-Plastic Composite (WPC) sandwich panel.

Combining the benefits of natural wood fibers and recycled plastics,

WPC sandwich panels offer a greener and more sustainable alternative to traditional building materials.

In this article, we will explore how WPC sandwich panels are spearheading the eco-friendly revolution in the construction sector,

promoting sustainable practices and redefining the way we build for a greener future.

The rise of WPC sandwich panels marks a significant shift towards more sustainable and environmentally responsible construction practices.

By harnessing the potential of renewable wood fibers and recycled plastics, these panels offer a range of eco-friendly benefits.

From reducing the demand for virgin wood and diverting plastic waste from landfills to minimizing energy consumption during production,

WPC sandwich panels exemplify the principles of circular economy and sustainability.

Moreover, their superior insulation properties, durability, and resistance to

environmental factors contribute to energy-efficient buildings with extended lifespans.

As we delve into the eco-friendly revolution brought about by WPC sandwich panels,

it becomes evident that they are setting new standards for building materials

and leading the way towards a greener, more sustainable future.

The Ingredients of Sustainability: Wood and Plastic

At the heart of the eco-friendly revolution lies the composition of WPC sandwich panels.

These panels combine the natural strength and aesthetics of wood with the versatility and durability of plastic.

The wood component in WPC sandwich panels is sourced from sustainable forestry practices,

ensuring that forests are managed responsibly, and the environmental impact is minimized.

Recycled plastics, often sourced from post-consumer waste,

further enhance the eco-friendliness of these panels by reducing

the volume of plastic ending up in landfills or polluting the environment.

By blending these renewable and recycled materials,

WPC sandwich panels reduce the need for traditional building materials

that require extensive natural resource extraction and contribute to deforestation.

As a result, these panels pave the way for a circular economy model,

where materials are continually recycled and reused, reducing the strain on the planet’s finite resources.

Sustainable Manufacturing: A Low-Carbon Footprint

The eco-friendliness of WPC sandwich panels is not limited to their composition; it extends to their manufacturing process as well.

The production of WPC materials consumes less energy compared to the

energy-intensive processes involved in producing traditional materials like steel or concrete.

The low-carbon footprint of WPC manufacturing contributes to a significant reduction in greenhouse gas emissions,

making them a preferred choice for sustainable construction projects.

Furthermore, advancements in technology have led to more efficient production

methods for WPC sandwich panels, ensuring minimal waste during the manufacturing process.

The optimization of material usage and recycling of excess materials align with

the principles of sustainability, reducing the environmental impact of these panels even further.

Energy Efficiency and Thermal Insulation

One of the key factors that make WPC sandwich panels revolutionary is their exceptional thermal insulation properties.

The combination of the WPC core and protective layers results in an efficient barrier against heat transfer.

This feature significantly reduces the need for artificial heating or cooling in buildings,

leading to substantial energy savings and lower greenhouse gas emissions.

Energy-efficient buildings constructed with WPC sandwich panels contribute to a greener and more sustainable urban landscape.

Reduced energy consumption not only benefits the environment but also translates into lower utility bills for building occupants,

promoting a more sustainable and economically viable living space.

Longevity and Durability: A Sustainable Investment

Sustainability is not only about using renewable resources but also about creating long-lasting products that withstand the test of time.

WPC sandwich panels excel in this aspect as well.

The inherent durability of these panels, combined with their resistance to moisture,

pests, and UV radiation, ensures a prolonged lifespan for buildings constructed with them.

By choosing WPC sandwich panels, construction projects can minimize the need for frequent replacements and renovations,

ultimately reducing the waste generated from construction debris.

The long service life of these panels aligns with the principles of sustainability,

where the focus is on creating enduring structures with minimal environmental impact.

The eco-friendly revolution brought about by WPC sandwich panels is redefining the construction industry’s approach to building materials.

By utilizing renewable wood fibers and recycled plastics,

these panels offer a greener and more sustainable alternative to traditional construction materials.

Their low-carbon footprint, energy efficiency, thermal insulation properties,

and durability make them a compelling choice for sustainable building projects.

As the world continues to prioritize environmental conservation and sustainable practices,

WPC sandwich panels are set to play an integral role in shaping the future of construction.

By fostering a circular economy and promoting energy-efficient buildings,

these panels exemplify the principles of sustainability, setting new standards for the eco-friendly revolution in the construction sector.

Embracing WPC sandwich panels represents a conscious step towards a greener, more sustainable future for generations to come.