In an era defined by environmental consciousness and resource optimization,

the construction industry is seeking innovative solutions to enhance building efficiency and sustainability.

As one of the game-changers in modern architecture,

Wood-Plastic Composite (WPC) sandwich panels have emerged as a promising alternative to traditional building materials.

With their unique composition and exceptional properties,

WPC sandwich panels offer the potential to significantly improve building efficiency while minimizing environmental impact.

In this article, we will conduct a comparative analysis of WPC sandwich panels against conventional building materials,

exploring how they enhance building efficiency, reduce energy consumption, and contribute to a greener future.

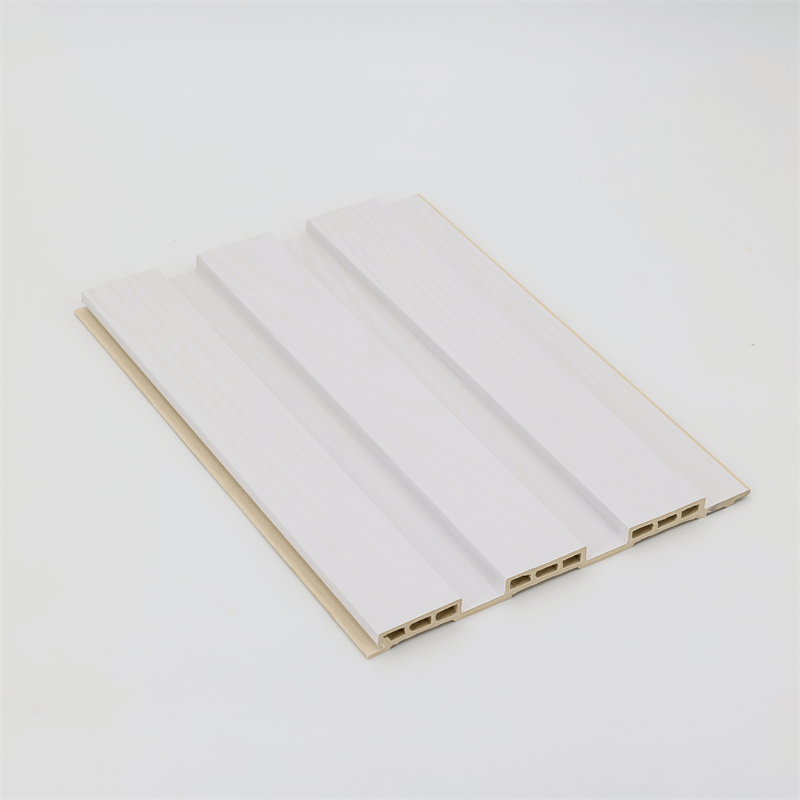

WPC sandwich panels, a cutting-edge building material,

have demonstrated their ability to enhance building efficiency through a comprehensive comparative analysis.

When compared to conventional materials like wood, concrete, and metal,

WPC sandwich panels exhibit superior thermal and acoustic insulation, lightweight construction, and moisture resistance.

These panels contribute to energy-efficient buildings, reduced carbon emissions, and minimized environmental impact.

Furthermore, their sustainability, durability, and low maintenance requirements make them a viable long-term investment.

As we delve into the comparative analysis of WPC sandwich panels, it becomes evident that they hold immense potential in

revolutionizing building efficiency and driving sustainable construction practices.

Thermal Insulation: Reducing Energy Consumption

One of the key factors that contribute to building efficiency is thermal insulation,

which regulates indoor temperatures and reduces the need for artificial heating or cooling.

In this aspect, WPC sandwich panels outperform traditional materials like concrete and metal.

The combination of wood fibers and plastic in WPC sandwich panels creates a

thermal barrier that significantly reduces heat transfer through walls and roofs.

As a result, buildings constructed with WPC panels maintain stable indoor temperatures,

leading to lower energy consumption and reduced utility bills.

In comparison, traditional building materials like concrete and metal have lower thermal insulation properties,

making them less efficient in maintaining comfortable indoor conditions.

Consequently, structures with conventional materials often rely heavily on energy-intensive HVAC systems to achieve thermal comfort,

resulting in higher energy consumption and increased carbon emissions.

Acoustic Insulation: Creating Serene Spaces

In addition to thermal insulation, acoustic performance is vital in enhancing building efficiency, particularly in urban environments with high noise levels.

WPC sandwich panels excel in acoustic insulation due to their unique composition.

The dense WPC core combined with the protective layers effectively blocks external noise, creating quieter and more serene interior spaces.

In contrast, conventional materials like metal and concrete have poorer acoustic insulation properties, allowing sound to pass through more easily.

This can lead to increased noise pollution inside buildings, negatively impacting occupants’ comfort, productivity, and well-being.

By choosing WPC sandwich panels, architects and developers can create spaces with enhanced acoustic performance, promoting a healthier and more conducive environment.

Lightweight Construction: Easier Installation and Reduced Costs

The lightweight nature of WPC sandwich panels presents several advantages during construction.

Compared to conventional materials like concrete and metal, these panels are easier to transport, handle, and install.

The reduced weight of WPC sandwich panels simplifies the construction process, leading to shorter project timelines and lower labor costs.

Moreover, the lightweight nature of WPC panels enables the construction of taller structures

with lower foundation requirements, further reducing construction costs and material usage.

This characteristic makes them ideal for a wide range of applications, including both new constructions and retrofitting projects.

Moisture Resistance: Prolonging Building Lifespan

Moisture infiltration is a common issue in buildings and can lead to mold growth, decay, and structural damage.

WPC sandwich panels demonstrate excellent moisture resistance due to the combination of wood fibers and plastic,

making them highly suitable for exterior applications and damp environments.

In contrast, conventional materials like wood are susceptible to rot and decay when exposed to moisture, requiring frequent maintenance and replacements.

By using WPC sandwich panels, building owners can prolong the lifespan of their structures,

reduce maintenance costs, and minimize the environmental impact associated with material replacements.

The comparative analysis of WPC sandwich panels against conventional building materials highlights their ability to enhance building efficiency and sustainability significantly.

With their superior thermal and acoustic insulation, lightweight construction, and moisture resistance,

WPC panels contribute to energy-efficient buildings, reduced carbon emissions, and minimized environmental impact.

Their sustainability, durability, and low maintenance requirements make them a viable long-term investment for the construction industry.

As architects, engineers, and developers prioritize building efficiency and environmental responsibility,

WPC sandwich panels emerge as a promising solution to meet these goals.

By incorporating these innovative panels into construction projects, the industry can pave the way towards a greener and more sustainable future,

where buildings are efficient, resilient, and conducive to the well-being of their occupants and the planet.